PRIMIX static mixers are applied in in-situ leaching processes for obtaining minerals, including, for example, uranium. In this process, the mixers are used to dilute sulphuric acid (H2SO4) to the correct concentration.

On-site leaching process for mineral extraction

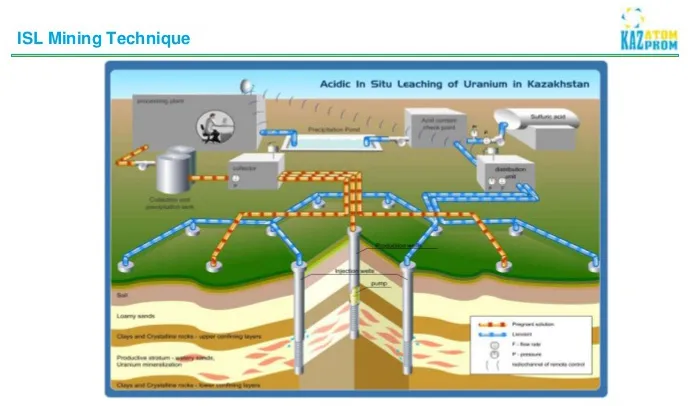

In the in-site leaching process, also referred to as in-situ recovery (ISR), or solution mining, minerals like uranium and copper can be retrieved from the ground through boreholes. In this process, the minerals that are present in the solid substance are dissolved in an acid that is pumped into the ground.

Applications

Application of static mixers for the dilution of sulphuric acid

PRIMIX supplies static mixers that are exceptionally suitable for the dilution of sulphuric acid to the correct concentration, yielding a very stable mixture. The dilution of sulphuric acid causes an exothermic reaction, which can result in the creation of local hotspots with high temperatures. This not only requires attention in the design, but also in the choice of materials. The PRIMIX sulphuric acid mixers are manufactured from PTFE, cladded in stainless or carbon steel. The PTFE, together with the robust and intelligent design, provides sufficient chemical resistance and is generally more cost-effective than a static mixer manufactured from Hastelloy® C276 material. The design has proven itself under the toughest conditions and currently there are hundreds of PRIMIX sulphuric acid mixers in use all over the world.

Sulphuric acid injection

The sulphuric acid is injected through a PFA-lined Caron or Stainless Steel T-piece, placed at the static mixer’s input.

Low pressure drop

The mixers are specially designed for the extreme corrosive application and offer a typical pressure drop of less than 0.5 bar.

More information about sulphuric acid dilution in a continuous process?

You can find more information about the mixing of sulphuric acid in a special case study sheet about H2SO4 dilution. Of course, you can always contact us or one of our partners directly as well.

English

English  Deutsch

Deutsch  Español

Español  Français

Français  Nederlands

Nederlands